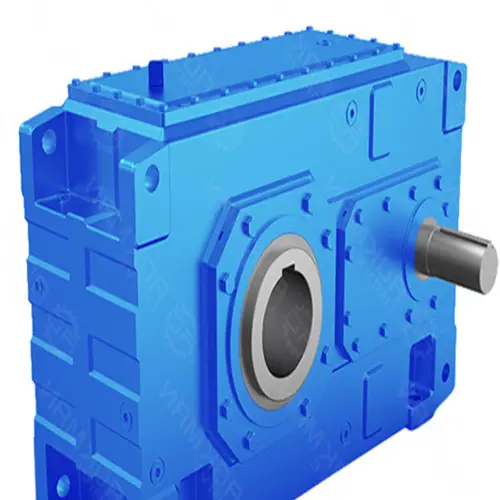

China Professional Parallel Shaft H Series Helical Gear Reducer Gearbox with Heavy-Duty Industrial Gearbox Portable Air Compressor

The Parallel shaft H series helical gear reducer gearbox with heavy-duty industrial gearbox is designed to meet the needs of various industrial applications. With its large torque range, it is capable of horizontal mounting and vertical mounting. It has high efficiency and a long lifespan, allowing high permissible axial and radial loads. Additionally, it is low noise, high reliability, and compact in structure. The output shafts are available in three types: CHINAMFG shaft, hollow shaft, and hollow shaft with shrink disk. It also has customization options according to the application.

Product Characteristics

The gearbox has a gear arrangement of helical hardened gearbox and a ratio of I=1/1.25~1/450. The rated torque ranges from 0.79n.M~900kn.M, and the rated power ranges from 4kw~3015kw. The input speed is 1500r/Min, 1000r/Min, or 750r/Min.

Packaging & Shipping

The product is securely packaged to ensure its safety during transportation. We offer various shipping options to meet your specific needs, including air, sea, and land transport.

Other Industrial Products We Offer

Our company mainly supplies various products for industrial use, such as agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, etc. We offer high-quality products, preferential prices, and considerate services. Customers are welcome to customize drawings and samples.

FAQs

1. What types of gearbox can your company produce?

Our company offers a wide range of gearbox products, including UDL series speed variator, RV series worm gear reducer, ATA series shaft mounted gearbox, X, B series gear reducer, P series planetary gearbox, and R, S, K, and F series helical-tooth reducer, among more than a hundred models and thousands of specifications.

2. Can your company produce customized gearboxes based on customer drawings?

Yes, we provide customized services for customers and can produce gearboxes based on your specific drawings or samples.

3. What are your payment terms?

Our payment terms are 30% advance payment by T/T after signing the contract and 70% before delivery.

4. What is your minimum order quantity?

Our minimum order quantity is 1 set.

5. What are the main characteristics of your parallel shaft H series helical gear reducer gearbox with heavy-duty industrial gearbox?

Our gearbox has a large torque range, high efficiency, a long lifespan, and high permissible axial and radial loads. It is low noise, high reliability, and compact in structure. The output shafts are available in three types: CHINAMFG shaft, hollow shaft, and hollow shaft with shrink disk. Additionally, our gearbox has customization options according to the application.

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy.

Introduction

Gearbox, also known as transmission, is an essential component that plays a significant role in transmitting power from the engine to the wheels in a vehicle. The performance characteristics of the gearbox are as follows:

1. Transmission Efficiency: The gearbox has high transmission efficiency, which can ensure that the engine’s power is transmitted to the wheels in a more efficient way.

2. Torque Multiplier: The gearbox can also act as a torque multiplier, which can increase the torque output of the engine to the wheels.

3. Gear Ratio: The gearbox can change the gear ratio, which can provide a wide range of speeds for the vehicle.

Types and Characteristics of Gearbox

There are several types of gearbox, including manual, automatic, continuously variable, and dual-clutch gearbox. Each type has its unique characteristics that suit different driving conditions.

1. Manual Gearbox: This type of gearbox requires the driver to change the gear manually. It is simple, reliable, and cost-effective, making it popular in many vehicles.

2. Automatic Gearbox: This type of gearbox can change gears automatically, making it more convenient for drivers. It is also suitable for reducing fuel consumption and improving driving comfort.

3. Continuously Variable Gearbox: This type of gearbox can continuously change the gear ratio, making it more fuel-efficient and smoother in operation.

4. Dual-Clutch Gearbox: This type of gearbox has two clutches, which can provide quick gear changes and improve driving dynamics.

Advantages of Gearbox Made of Different Materials

The gearbox can be made of various materials, including aluminum alloy, cast iron, steel, and magnesium alloy. Each material has its advantages and disadvantages.

1. Aluminum Alloy: This material is lightweight, which can reduce the overall weight of the vehicle and improve fuel efficiency.

2. Cast Iron: This material is durable and can withstand high loads, making it suitable for heavy-duty applications.

3. Steel: This material is strong and can resist wear and tear, making it suitable for high-speed applications.

4. Magnesium Alloy: This material is lightweight and has good heat dissipation, making it suitable for high-performance applications.

Application of Gearbox

The gearbox is widely used in various industries, including the automotive industry, industrial machinery, agricultural equipment, wind turbines, marine applications, and many others. Its use reflects its value and importance in various fields.

Future Development Trends and Opportunities

The gearbox industry is continuously evolving, and there are many development trends and opportunities in the market. Some of these trends include:

1. Lightweight and Compact Design: The demand for lightweight and compact gearbox design is growing due to the need for more fuel-efficient vehicles.

2. Electrification: As more vehicles become electrified, there is a growing demand for electric gearbox systems that can handle higher torque loads.

3. Advanced Materials: The use of advanced materials, such as carbon fiber, can improve the strength and durability of the gearbox.

How to Choose a Suitable Gearbox

Choosing a suitable gearbox requires consideration of several factors, including load requirements, ratio selection, type of gearbox, environmental factors, maintenance, and durability.

1. Load Requirements: The gearbox should be selected based on the load requirements of the application. This includes the weight of the vehicle, the torque output of the engine, and the maximum speed of the vehicle.

2. Ratio Selection: The gearbox should be selected based on the desired gear ratio. This includes the number of gears and the gear ratios of each gear.

3. Type of Gearbox: The type of gearbox should be selected based on the driving conditions and the vehicle’s purpose.

4. Environmental Factors: The gearbox should be selected based on the environmental factors, such as temperature, humidity, and vibration.

5. Maintenance and Durability: The gearbox should be selected based on its maintenance requirements and durability.

Conclusion

In conclusion, the gearbox is an essential component in various industries, and its performance characteristics, types, materials, and applications make it a vital part of many vehicles and machines. The future development trends and opportunities in the gearbox industry are promising, and choosing a suitable gearbox requires careful consideration of several factors.