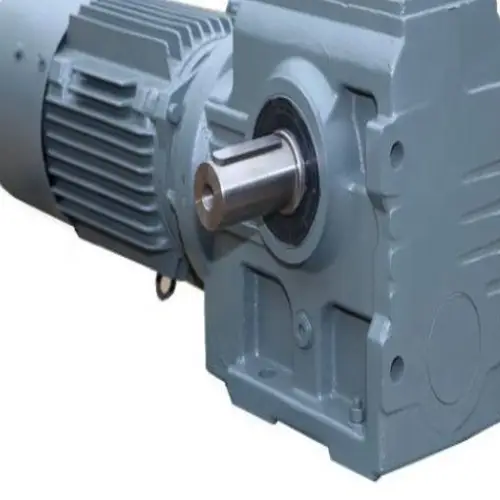

High-Quality Small 90 Degree Bevel Transmission Gearbox for Grinding Mill

If you are looking for a durable and efficient gearbox for your grinding mill, then our Small 90 Degree Bevel Transmission Gearbox is just what you need. Our gearbox has a high modular design with biomimetic surface, which is protected by our intellectual property right. Using German worm hob, we process the worm wheel and create a unique gear geometry that provides high torque, efficiency, and long life. This gearbox can achieve direct combination for two sets of gearboxes, and can be mounted in several ways, including foot mounted, flange mounted, and torque arm mounted. The output shaft can be CHINAMFG shaft, or a hollow shaft.

Detailed Photos

We have included detailed photos of our Small 90 Degree Bevel Transmission Gearbox, so you can see exactly what you are getting.

Product Parameters

Our gearbox is made from high-quality materials, including cast iron/ductile iron for the housing material, and 20CrMnTi alloy steel for the gears. The surface hardness of the gears is HRC58°~62°, and the core hardness is HRC33~40. The input/output shaft is made of 42CrMo alloy steel, and has a hardness of HRC25~30. Our gears are accurately ground, with a machining precision of 6~5 Grade. We use GB L-CKC220-460 or Shell Omala220-460 lubricating oil, and our gearbox has an efficiency of 94%~96% (depending on the transmission stage).

Our Advantages

We are a direct factory with advanced production equipment and a strong development team. We have the capacity to produce high-quality gearboxes, AC motors, and related spare parts. Our products are widely used in various industries, including Metallurgy, Chemicals, Textile, Medicine, Wooden, and more. We offer quality products at a competitive price, and our considerate services have earned us a reputation as a reliable supplier.

Packaging & Shipping

We use professional packaging to ensure that our gearboxes arrive safely and free from damage. We ship our products worldwide, and can provide an efficient and reliable delivery service.

Certifications

Our products have been certified by various organizations, including ISO9001, CE, and SGS. These certifications ensure that our products meet the highest standards of quality and safety.

FAQs

Q: Can this gearbox be customized to meet specific requirements?

A: Yes, we welcome customers to provide us with drawings and samples so that we can customize our gearboxes to meet their specific needs.

Q: What is the delivery time for this gearbox?

A: If we have the gearbox in stock, the delivery time is usually 5-10 days. If we do not have the gearbox in stock, the delivery time is usually 15-20 days.

Q: What is the noise level of this gearbox?

A: The maximum noise level of our gearbox is 60~68dB.

Q: Can I purchase a sample of this gearbox for quality testing?

A: Yes, we are glad to accept trial orders for quality testing.

Q: How do I choose the right gearbox for my grinding mill?

A: You can refer to our catalog to choose the gearbox that meets your requirements, or we can help you choose the right gearbox when you provide us with the technical information of the required output torque, output speed, and motor parameters.

Our company offers a wide range of industrial products, including agricultural gearboxes, power output shafts, sprockets, fluid couplings, worm gear reducers, gears and racks, roller chains, pulleys, planetary gearboxes, timing pulleys, bushings, and more. We are committed to providing high-quality products at preferential prices, and we welcome customers to contact us for customized drawings and samples.

All the content of this page is from the Internet. The content is only for reference for product selection. Our products are replacement parts and not original spare parts. We are not the holder of the original trademarks of the content. Our products are only suitable for after-sales replacement parts and not original spare parts. Our replacement parts can be perfectly adapted to the original spare parts. If you need to buy original spare parts, please contact the original factory to buy.

Introduction

Gearbox, also known as transmission, is an essential component that plays a significant role in transmitting power from the engine to the wheels in a vehicle. The performance characteristics of the gearbox are as follows:

1. Transmission Efficiency: The gearbox has high transmission efficiency, which can ensure that the engine’s power is transmitted to the wheels in a more efficient way.

2. Torque Multiplier: The gearbox can also act as a torque multiplier, which can increase the torque output of the engine to the wheels.

3. Gear Ratio: The gearbox can change the gear ratio, which can provide a wide range of speeds for the vehicle.

Types and Characteristics of Gearbox

There are several types of gearbox, including manual, automatic, continuously variable, and dual-clutch gearbox. Each type has its unique characteristics that suit different driving conditions.

1. Manual Gearbox: This type of gearbox requires the driver to change the gear manually. It is simple, reliable, and cost-effective, making it popular in many vehicles.

2. Automatic Gearbox: This type of gearbox can change gears automatically, making it more convenient for drivers. It is also suitable for reducing fuel consumption and improving driving comfort.

3. Continuously Variable Gearbox: This type of gearbox can continuously change the gear ratio, making it more fuel-efficient and smoother in operation.

4. Dual-Clutch Gearbox: This type of gearbox has two clutches, which can provide quick gear changes and improve driving dynamics.

Advantages of Gearbox Made of Different Materials

The gearbox can be made of various materials, including aluminum alloy, cast iron, steel, and magnesium alloy. Each material has its advantages and disadvantages.

1. Aluminum Alloy: This material is lightweight, which can reduce the overall weight of the vehicle and improve fuel efficiency.

2. Cast Iron: This material is durable and can withstand high loads, making it suitable for heavy-duty applications.

3. Steel: This material is strong and can resist wear and tear, making it suitable for high-speed applications.

4. Magnesium Alloy: This material is lightweight and has good heat dissipation, making it suitable for high-performance applications.

Application of Gearbox

The gearbox is widely used in various industries, including the automotive industry, industrial machinery, agricultural equipment, wind turbines, marine applications, and many others. Its use reflects its value and importance in various fields.

Future Development Trends and Opportunities

The gearbox industry is continuously evolving, and there are many development trends and opportunities in the market. Some of these trends include:

1. Lightweight and Compact Design: The demand for lightweight and compact gearbox design is growing due to the need for more fuel-efficient vehicles.

2. Electrification: As more vehicles become electrified, there is a growing demand for electric gearbox systems that can handle higher torque loads.

3. Advanced Materials: The use of advanced materials, such as carbon fiber, can improve the strength and durability of the gearbox.

How to Choose a Suitable Gearbox

Choosing a suitable gearbox requires consideration of several factors, including load requirements, ratio selection, type of gearbox, environmental factors, maintenance, and durability.

1. Load Requirements: The gearbox should be selected based on the load requirements of the application. This includes the weight of the vehicle, the torque output of the engine, and the maximum speed of the vehicle.

2. Ratio Selection: The gearbox should be selected based on the desired gear ratio. This includes the number of gears and the gear ratios of each gear.

3. Type of Gearbox: The type of gearbox should be selected based on the driving conditions and the vehicle’s purpose.

4. Environmental Factors: The gearbox should be selected based on the environmental factors, such as temperature, humidity, and vibration.

5. Maintenance and Durability: The gearbox should be selected based on its maintenance requirements and durability.

Conclusion

In conclusion, the gearbox is an essential component in various industries, and its performance characteristics, types, materials, and applications make it a vital part of many vehicles and machines. The future development trends and opportunities in the gearbox industry are promising, and choosing a suitable gearbox requires careful consideration of several factors.